.jpg)

.jpg)

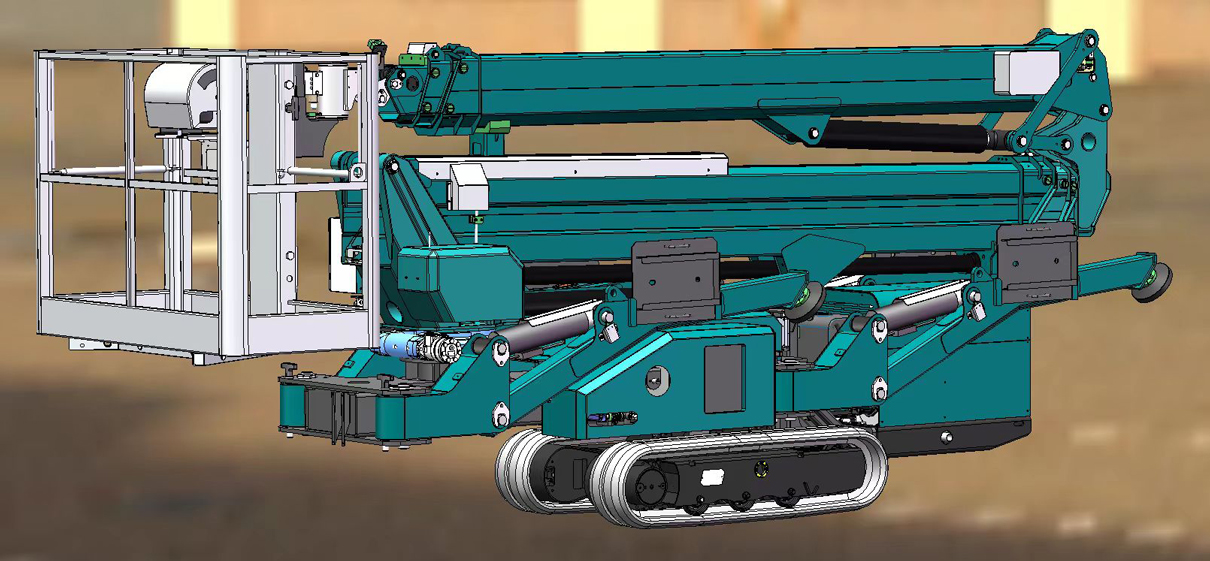

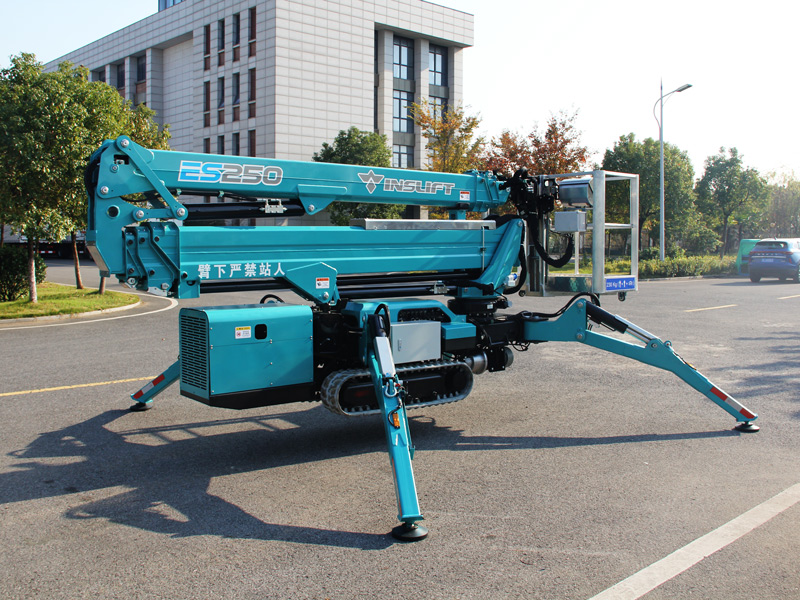

When a product has been in service for many years, many of its components may experience aging and wear. However, for many products, achieving a product's rejuvenation and extending the lifecycle of spider lifts and aerial work platforms can be as simple as replacing these aging or critical safety components.

The reuse of components, based on absolute safety, is not only the utmost protection of our environment but also a further drive towards green and eco-friendliness to protect our planet.

Remanufacturing involves not only hardware upgrades and reuse but also optimization of electronic control software, giving remanufactured equipment greater intelligence and environmental friendliness, thus extending its lifespan.

As the domestic equipment industry rapidly evolves, the demand for high-quality machinery continues to rise. Our remanufacturing model is pivotal not only for our development but also for meeting the needs of the market and our users.

Through our buyback and refurbishment initiatives, we enhance product rental rates, residual values, and circulation rates while significantly extending the lifecycle of our equipment. This approach provides customers with added assurance when purchasing, helping to reduce both acquisition and operational costs.

Our commitment to high-end remanufacturing exemplifies a sustainable economic model that fosters a new ecosystem. As industry pioneers, we are dedicated to promoting green and sustainable development while delivering exceptional service to our customers.